|

MACHINE VISION

|

|

|

|

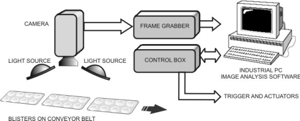

Images

from the camera are digitized and stored in the computer where it is

automatically analyzed to extract the required information. The camera

can either be a standard video camera, or in the cases of products on a

conveyor, a linear array sensor which generates a high resolution image

on a line-by-line basis. It is usually not necessary to store an ideal

image of the item being inspected. Rather, certain features of a correct

item are combined to form a model of an ideal product. The same features

are extracted from each inspected item and compared with the model. In

this way factors such as positional alignment, changes in illumination

levels and tolerances in specifications are accommodated. Often a

conventional computer is not fast enough for real applications. In such

cases special hardware must be used for parts of the problem. This

can take the form of custom designed preprocessing hardware or

commercially available high-speed vision architectures.

BY MVIS YOU CAN...

|

|

|

|